Big in size and big on performance.

Electronic wheel balancers for car, van and motorcycle wheels. Appealing design and shapes designed to allow maximum access to inside the wheel. The side accessory compartment has been designed to store universal flanges, cones and bushes. LED spotlight to light-up the work area and make it easier to clean the rim, check the wheel and apply weights. Quickly and intuitive sensitivity calibration. AWD automatic sensor (Auto width Device) for contactless measurement of wheel width (optional) New automatic wheel clamping system, with constant torque, for shorter operative times and higher centering accuracy.

FEATURES

Electronic wheel balancers for car, van and motorcycle wheels. Appealing design and shapes designed to allow maximum access to inside the wheel.

WEIGHT TRAY

Appealing design and shapes designed to allow maximum access to inside the wheel. The numerous weight-holder trays, compartments for cones and accessories and the adjustable monitor guarantee maximum work ergonomics. The tray is made of highly resistant materials. The anvil can be used to prepare or regenerate clip weights without damaging the weight tray.

STORAGE FOR ACCESSORIES

The side accessory compartment has been designed to store universal flanges, cones and bushes. The work area is kept tidy and accessories can be easily accessed and do not get damaged.

WHEEL GUARD

The new wheel guard allows use whit wheel sizes up to 44”.

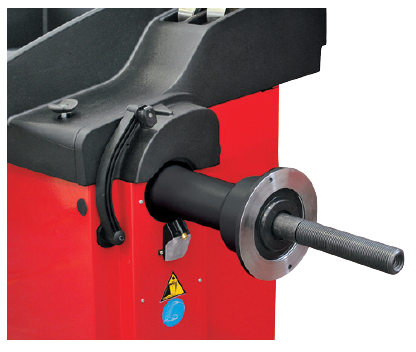

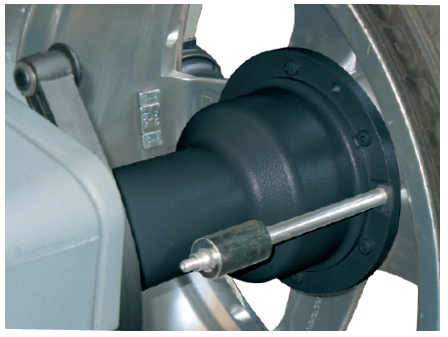

SPIN UNIT

Sized to work with high offset wheels without the need for additional spacers. Automatic brake at the end of the spin. Reduced cycle time and high performance. The “zero” maintenance motor and highly innovative design solutions garantee reliability, sturdiness and high work loads.

LED ILLUMINATOR AND POSITIONING WEIGHT

LED spotlight to light-up the work area and make it easier to clean the rim, check the wheel and apply weights. The adhesive weights can be positioned extremely rapidly using the laser pointer at 6 o’clock.

CALIBRATION

Quickly and intuitive sensitivity calibration. The sample weight supplied with the machine is simply applied directly to the spin unit, ensuring maximum precision and eliminating operator error.

WHEEL DIMENSION DETECTION

Automatic wheel positioning in the point where the balancing weight has to be applied and electrical positioning brake (RPA). Electronic input of wheel diameter and distance with FSP function which automatically activates the balancing programmes, avoiding keypad selection.

Three modes to position the adhesive weights: with the weight holfer clip (optional), with the 6 o’clock laser indicator or manually at 12 o’clock.

AWD SONAR DEVICE

AWD automatic sensor (Auto width Device) for contactless measurement of wheel width (optional).

SPECIFICATION VIEW

| Pneumatic air supply pressure | 6/8 bar |

| Shaft diameter | 40 mm |

| Spinning speed | 90 - 130 rpm |

| Unbalance measurement accuracy | 1 g |

| Average measurement time | 7s |

| Rim width setting range | 1.5" - 20" |

| Rim diameter setting range | 1" - 35" |

| Rim diameter measurement range | 11" - 28" |

| Max wheel width (with guard) | 600 mm |

| Max wheel diameter (with guard) | 1117 mm |

| Max wheel / machine distance | 275 mm |

| Max wheel weight (ground fastening) | 75 kg |

| Machine weight (without accessories) | 198 kg |