CORGHI (ITALY) Diagnostic tyre changer with LEVA LA LEVA (without lever) mounting/demounting technology.

MASTER CODE now has 4 automated work cycles to make procedures increasingly fast, simple and absolutely safe for integrity of the rim and the tyre. The objective of these new and improved automatisms is to increase performance and efficiency with all wheel types and to reduce the use of that increasingly precious commodity - time. The computerised Touch Screen system guides the operator through all procedures and suggests the best possible solution to any problem encountered.

MASTER CODE is compatible with all tyre types, from Run Flat-UHP tyres to both small and large balloon tyres. With these features, together with the indispensable and exclusive demounting system, the Smart Corghi System, the MASTER CODE rewrites the DNA of tyre changer systems, confirming once again its inventors as the only people capable of driving the continuous evolution of the industry.

FEATURES

WHEEL DATA SELF-ACQUISITION

• Self acquisition of wheel dimensions

• Automatic tool positioning

• Intelligent and very user friendly

• Four wheel type settings

• Quick, safe, ergonomic

• AUTOMATIC or MANUAL work cycle selection

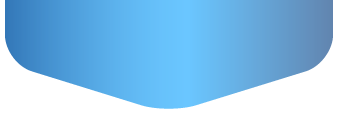

SMART CORGHI SYSTEM

• Smart Corghi System demounting procedure

• Minimised tyre stress

• Absolutely NO contact with rim!!!

• Automated, synchronised tyre demounting and mounting

DUAL BEAD BREAKER WITH CONTROLLED PENETRATION

• Dual pneumatic bead breaker penetrator

• Maximum rigidity

• Maximum efficiency and precision

• Dual opposed bead breaker discs with separately controlled cylinders

• Automatic repositioning of upper bead breaker arm

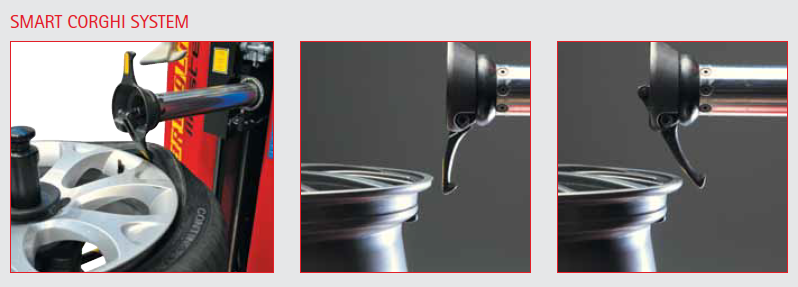

AUTOMATIC DIRECT LUBRICATION

• Automatic direct lubrication of lower and upper bead

• Direct lubrication during dynamic bead breaking ensures maximum efficiency even with most stubborn tyres

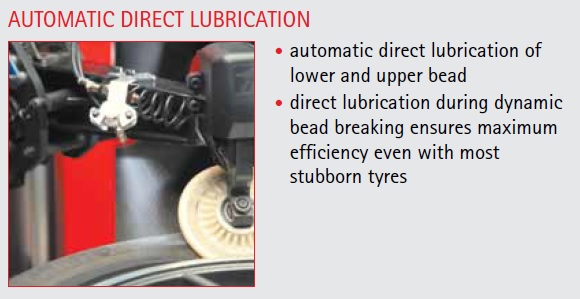

MOBILE CONTROL CONSOLE

• Freely adjustable mobile control console

• Simple, quick and intuitive controls

• Extreme user friendly manual cycle

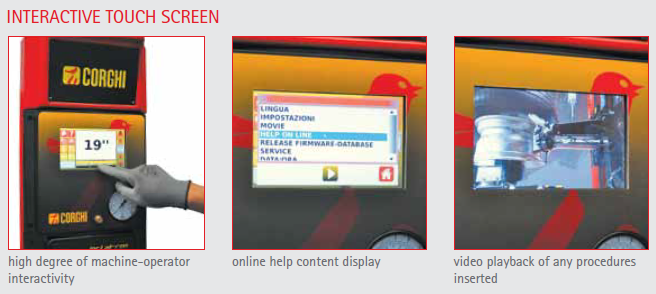

INTERACTIVE TOUCH SCREEN

• Interactive multifunctional TFT-LCD TOUCH SCREEN interface with microprocessor control

• USB port for software databases update, and for loading files and videos

• Playback capability for demonstration videos

• Scheduled maintenance reminder, self-diagnosis, sensor state check and fault indication

• Online help with instruction manual and special procedures (WDK, BSR, RFT, UHP)

• Camera active during automatic work cycle

NEW INTELLIGENT ELECTROMECHANICAL TURNTABLE

• Intelligent electromechanical turntable

• New patented wheel clamp system

• Fast, simple

• Reliable for all wheel types (comes equipped with additional specific flanges)

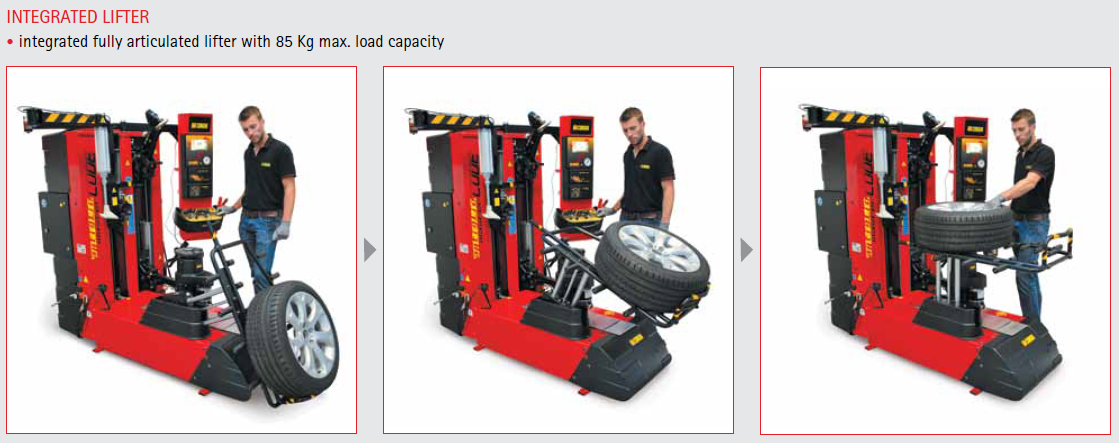

INTEGRATED LIFTER

• Integrated fully articulated lifter with 85 Kg max. load capacity

INTEGRATED TPMS

• For checking functionality of sensors and viewing important information

BEAD DEPRESSOR

• Bead depressor with adjustable working height

• Depressor shape ideal for RFT tyres

• WDK homologated

LATEST GENERATION INVERTER MOTOR

• Second speed also available in reverse rotation mode

• Torque control

• Controlled acceleration curve to safeguard tyre

“INFLATRON” ELECTRONIC INFLATOR

• Integrated, automated inflation and deflation system

• Permits automatic inflation of tyre while operator performs other operations for optimised time use

• Overpressure inflation for bead insertion

• Touch screen user interface

• Bar, PSI and kPa scales

• End of cycle indicator

VIDEO CAMERA WITH IMAGE RECALLABLE FROM SCREEN

• Video camera activatable during operations, positioned for a clear view of the lower side of the tyre always active in the AUTOMATIC cycle

TREAD DEPTH PROBE

• Tread depth measurement

• Tread depth values: shown with yellow background to indicate values near minimum limit

• Tread depth values: shown with red background to indicate values below minimum limit

TYRE TEMPERATURE SENSOR (in accordance with WDK requisites)

• Real-time tyre and bead temperature sensor

• Maximum measurement speed and precision (resolution 0.1°C), with value displayable in Centigrade or Fahrenheit

• Intuitive colour-based temperature indication in accordance with WDK requisites for working with RFT and UHP tyres

SPECIFICATION VIEW

| Wheel dimension range | |

| Rim diameter | 13" - 32" |

| Max tyre diameter | 1200 mm (47") |

| Turntable | |

| Clamping | Automatic |

| Drive system | 2 speed inverter motor |

| Rotation torque | 1200 Nm |

| Rotation speed | 7 - 20 rpm |

| Bead breaker | |

| Max bead breaking range | 19" |

| Upper bead breaker force | 7300 N |

| Lower bead breaker force | 7300 N |

| Wheel lifter load capacity | 85 kg |

| Power supply | |

| Electric 1PH | 230V - 0.98 kW 50/60 Hz |

| Electric 1PH (alternative) | 115V - 0.98 kW 50/60 Hz |

| Pneumatic operating pressure | 8 - 10 bar |

| Weight | 595 kg |